Manufacturing Of Clay Bricks(Part 1)

The manufacturing of clay bricks is carried out in a number of stages which are as follows:-

- Selection And Preparation Of Clay

- Moulding

- Drying

- Burning

Selection And Preparation Of Clay:-

First of all, suitable deposits of clay are first located and thoroughly tested for the quality of brick making. Then, the clay for bricks is prepared in the following order:-

Unsoiling:-

- About 20 cm of the top layer of the soil is removed after clearing the trees and vegetation as it generally contains stones, pebbles, gravel, roots, etc.

- The soil used for making building bricks should be free of gravel, coarse sand( having particle size more than 2 mm), lime and kankar particles, organic matter, etc.

Digging:-

- After unsoiling, the proportion of additives such as fly ash, sandy loam, rice husk ash, stone dust, etc. should be spread over the plane ground surface on a volume basis.

- The soil mass is then dug out, puddled, watered and leftover for weathering and further processing.

- The digging operation should be done before rains.

Weathering:-

- Stones, gravels, pebbles, roots, etc. are removed from the dug soil and it is heaped on level ground in layers of 60-120 cm.

- This soil is left in heaps and for at least one month it is exposed to the weather if weathering is considered necessary for the soil.

- It is done to develop homogeneity in the mass of soil, particularly if they are from different sources.

- It is also done to eliminate the impurities which get oxidized.

- To some extent, soluble salts in the clay also get eroded by rain which may otherwise cause scumming at the time of burning of the bricks in the kiln.

- The soil should be turned over at least twice and it should be ensured that the entire soil is wet throughout the period of weathering.

- Water may be sprayed in order to keep the soil wet as often as necessary.

- By exposing the soil to weather, the strength and plasticity of the clay are improved.

Blending:-

- To modify the composition of the soil, it is mixed with sandy-earth and calcareous-earth in suitable proportions.

- To obtain the right consistency for moulding, a moderate amount of water is mixed to the clay.

- The mass is mixed uniformly with spades.

- For easy mixing and workability, the addition of water to the soil at the dumps is necessary.

- The addition of water to the clay should be controlled in such a way that it may not create a problem in moulding and drying.

- The size and shape of the finished brick may get affected by excessive moisture.

Tempering:-

- Tempering consists of kneading the earth with feet so as to make the mass stiff and plastic.

- In this stage, the clay is brought to a proper degree of hardness and it is made fit for moulding.

- It should preferably be carried out by storing the soil in a cool place in layers of about 30 cm thickness for not less than 36 hours as it will ensure the homogeneity in the mass of clay for further processing.

- For manufacturing good brick, tempering is done in pug mills and the operation is called pugging.

|

| Pug Mill(Image From Book By S.K. Duggal) |

- Steam, diesel or electric power may be used for the pugging operation in a pug mill.

- Blended clay along with required water, is fed into the pug from the top.

- The knives cut through the clay and break all the lumps of clay when the shaft rotates.

- The thoroughly pugged clay is then taken out from the opening which is provided in the side near the bottom.

- The yield from the pug mill is about 1500 bricks.

Moulding:-

- It is a process of giving a required shape to the brick from the prepared clay.

- Moulding may be carried out by hand or by machines.

|

| Details Of A Mould(Image From Book By S.K. Duggal) |

- The process of moulding of bricks may be the hand moulding(soft-mud), the stiff-mud(machine moulding) or the dry-press process(moulding using a maximum of 10% water and forming bricks at higher pressure).

- The Soft-mud process is used to make fire bricks.

- The Dry-press method is used for making roofing, floor and wall tiles.

- The Stiff-mud process is used for making all the structural clay products.

Types of Moulding:-

Hand moulding:-

Hand moulding is further divided into two types:-

Ground moulding:-

- This method is adopted when a large and level land is available.

- The ground is levelled and sand is sprinkled on it.

- The bricks obtained from this moulding don't have a frog and their surface becomes too rough.

- Moulding blocks or boards are used at the base of the mould to overcome these defects.

- The process consists of shaping in hands a lump of well-pugged clay, slightly more than the size of the brick volume.

- It is then rolled into the sand and with a jerk, it is dashed into the mould.

- The moulder then gives blows with his fists and presses the clay properly in the corners of the mould with his thumb.

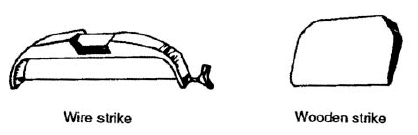

- The extra clay on the top surface is removed with a strike(sharp edge metal plate) or with a thin wire stretched over the mould which has to be dipped in water every time it is used.

|

| Wire Strike And WoodenStrike(Image From Book By S.K. Duggal) |

- After this, the mould is given a gentle slope and is lifted leaving the brick on the ground to dry.

- If the mould is dipped in water every time after use, such preparation of bricks is known as slope moulded bricks.

- If fine sand or ash is sprinkled on the inside surface of the mould every time after use, such preparation of bricks is called sand moulded bricks.

Table moulding

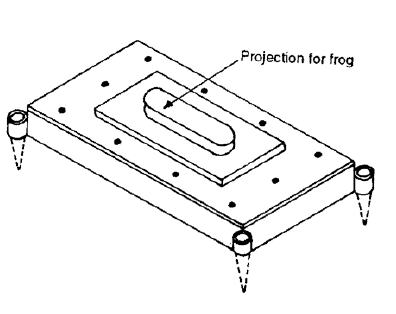

- The bricks are moulded on stock boards nailed on the moulding table.

|

| Moulding Table(Image From Book By S.K. Duggal) |

- Stock boards have the projection for forming the frog.

|

| Stock Board(Image From Book By S.K. Duggal) |

- The process of filling clay in the mould is the same as in the ground moulding process.

- After this, a thin board called pallet is placed over the mould.

- The mould containing the brick is then smartly lifted off the stock board and inverted so that the moulded clay along with the mould rests on the pallet.

- The mould is then removed in the same way as in the ground moulding and the brick is carried to the drying site.

- The cost of brick moulding increases when table moulding is adopted.

Machine Moulding:-

Machine moulding is further divided into two types:-

Plastic Method:-

- It is a quick and economical method.

- The pugged, stiffer clay is forced through a rectangular opening of a brick size by means of an auger.

|

| Plastic Moulding(Image From Book By S.K. Duggal) |

- Clay comes out of the opening in the form of a bar.

- The bricks are cut by a frame which consists of several wires at a distance of brick size.

- These bricks are also known as wire-cut bricks.

Dry-press Method:-

- The moist and powdered clay is fed into the mould on a mechanically operated press.

- This clay in the mould is subjected to high pressure and takes the shape of bricks.

- The bricks obtained from this process are denser, smoother and uniform than the ordinary bricks.

- They are burnt carefully as they are likely to crack.

- These bricks are also known as pressed bricks.

For Manufacturing of Bricks (Part 2) kindly visit- https://www.akhandduttaengineering.in/2020/08/manufacturing-of-bricks-part-2.html

*Self Typed

*Source- Internet, Books, Self-Analysis